Profile

15

Boston, Massachusetts

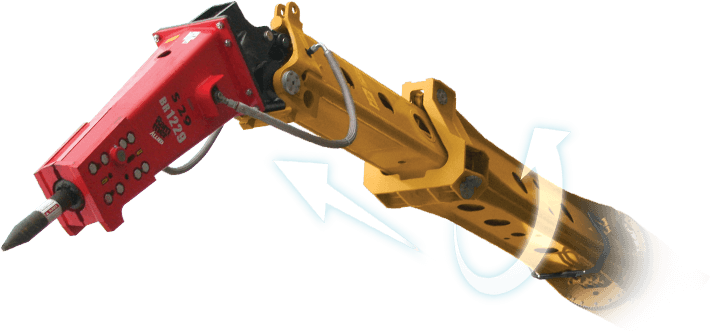

XL 2300 IS SPECIALLY EQUIPPED FOR RAIL SYSTEM MAINTENANCE

Massachusetts Bay Transportation Authority performs ongoing maintenance on a rail system that is a major portion of the Boston area's infrastructure. The project involves removing and installing rail and rail bed, often working in remote locations. Plus, equipment must be able to move and work inside tunnels and other areas of limited mobility.

Gradall Versatility Advantages

The compact size and low-overhead working capabilities of the Gradall® Model XL 2300 excavator are well suited for the Boston railway work. The machine moves readily through the many narrow railroad tunnels and underpasses, and the telescoping boom requires only a fraction of the overhead space needed for a conventional knuckle boom. The specially equipped Model XL 2300 has uniquely located outriggers that provide extra stability when working off either side of the machine. Front and rear guide wheels combined with four wide tires and special rims propel the Model XL 2300 quickly to locations requiring maintenance, which would otherwise be inaccessible. The special mobility package is also designed to avoid interfering with the high voltage 'third rail' that trains use for a power source. "We use the machine almost every day," said Jack Marrow, the operator. "The size of the bucket is just right for cleaning between the rails. Now we have plans to install a rotary mower at the end of the boom to clear the brush and vegetation that grows alongside the tracks."

SELECT APPLICATION

- Railway Maintenance

SELECT MODEL

- Highway Wheeled

- Rough Terrain Wheeled

BUILT TO WORK.

BUILT TO LAST.

Manufactured in America with the highest quality standards, Gradall Metal Mill maintenance machines are built for hard work and a long machine life. Backed by the Gradall name, a well-known and respected brand worldwide in the construction industry.