NEW PHILADELPHIA, OH — Capitalize on the designed-in versatility of your Gradall Series III hydraulic excavator with a mower attachment. Designed for quick, efficient work, Gradall's wheeled and railway maintenance excavator models can use mower attachments to clear away brush, long grass and weeds and other vegetation along highway boundaries and railway tracks.

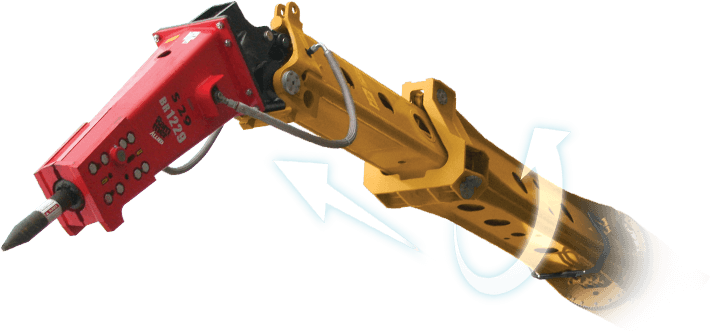

Often replacing the need for extra maintenance equipment, the Gradall excavator's telescoping, tilting boom can be used to position a mower at a 90-degree angle to control vegetation along fence rows, buildings and other structures. Or, the boom can be raised and tilted to correctly position the mower to cut back overgrown tree limbs that can obstruct traffic on roads.

Attaching a mower to the Gradall excavator boom can be accomplished quickly thanks to a special Gradall mounting bracket that easily interfaces with mower attachments manufactured by both Alamo and Tiger - both owned by the Alamo Group which owns Gradall Industries. Also, a hydraulic motor on the mowers eliminates the requirement for a case drain so there's no need to modify standard Gradall auxiliary hydraulic hoses in the Gradall boom.

Mowers are available in a range of styles and sizes including 50 and 60-inch rotary and 48-inch flail. For information, contact an authorized distributor or call Gradall at (800) 445-4752. You also can use the interactive Gradall distributor locator map.

All Gradall excavators are designed, built and supported by Gradall Industries, Inc., with processes that meet ISO 9001-2008 standards. Gradall Industries is wholly owned by the Alamo Group.

This news release contains forward-looking statements within the meaning of the Private Securities Litigation Reform Act of 1995. Forward-looking statements are not guarantees of future performance and involve a number of risks and uncertainties that could cause actual results to differ materially from those indicated by the forward-looking statements. Important factors that could cause actual results to differ materially from those suggested by the forward-looking statements include, but are not limited to, the following: (i) general economic and market conditions, including political and economic uncertainty in areas of the world where we do business; (ii) varying and seasonal levels of demand for our products and services; (iii) risks associated with acquisitions; (iv) credit risks from our financing of customer purchases; (v) risks arising from dependence on third-party suppliers; and (vi) costs of raw materials and energy, as well as other risks as detailed in the Company's SEC reports.

BUILT TO WORK.

BUILT TO LAST.

Manufactured in America with the highest quality standards, Gradall Metal Mill maintenance machines are built for hard work and a long machine life. Backed by the Gradall name, a well-known and respected brand worldwide in the construction industry.