Gradall Industries, Inc., has introduced a collection of highly productive Railway Maintenance Machines, delivering an ideal combination of on and off-rail mobility as well as handling a wide range of maintenance and construction jobs for railroads, municipal railways, city transit systems and others involved in rail construction, repair and right-of-way work.

The Gradall machines are distinguished by their low-profile, long-reach capabilities using the world-famous telescoping, tilting Gradall boom design. With a 220-degree full boom tilt capability, Gradall machines can efficiently use a range of attachments to build and repair rail crossings, clean up landslides, replace rails, spread ballast and cut back overhanging trees and other vegetation.

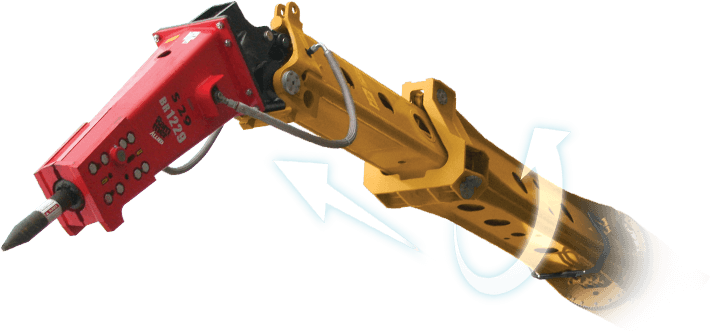

For even more attachment positioning versatility, Gradall offers a Kinshofer Nox-Tiltrotator boom-end option, featuring 360-degree continuous rotation and an extra 110 degrees of tilt motion to position buckets, tree limb shears and other attachments with more precision and in more locations than any other maintenance machine.

The Gradall carrier’s short rear tail swing and low-profile telescoping boom create a compact profile, allowing Gradall machines to work efficiently under bridges and inside tunnels where knuckle booms won’t fit.

Gradall is famous globally for introducing wheeled excavator mobility on highways as well as dirt. Gradall Railway Maintenance Machines can be quickly driven to the rail crossing, where carriers are positioned over the tracks. The rail gear system is quickly lowered into place, allowing the machine to move easily to one or more track repair and maintenance locations.

Two rail systems are available to deliver efficient travel along with the security of automatic digging brakes:

• The standard guide rail system uses the carrier’s wheels for mobility and extra stability while digging, replacing rails and ties, or moving material. Travel speed is 18 to 20 mph with this system.

• An optional hydrostatic drive rail gear system, with wheels raised, speeds the machine to job sites at about 14 mph. When working, wheels can be lowered for enhanced stability.

Choose highway speed or on/off pavement models

Gradall offers Railway Maintenance Machines in various sizes and capacities, designed in two styles to meet varying off-rail mobility needs:

• Highway speed models can be driven over highways at 60 mph, without the need for a lowboy trailer. This enables them to get to rail crossings quickly and then back to the safety of the equipment yard at night.

• On/off pavement models efficiently travel over pavement at speeds typically exceeding 15 mph. After traveling over rails to the work site, these models demonstrate their exceptional stability, working in any direction.

A host of standard operator cab features include air conditioning, removable front window, a large adjustable seating module and a switch to select Gradall, SAE or Deere joystick patterns. Highway speed carrier advantages include an automatic transmission.

Machines have almost 70 percent parts commonality, simplifying the task of maintaining inventories to complete common service functions. These machines also have longer routine service intervals, and most service locations can be reached from ground level. A network of authorized distributors supports all Gradall excavators, supplying service advice and authorized Gradall parts.

Manufactured only in America, Gradall models meet or exceed ISO 9001-2008 standards for quality. For more information, including railway work case histories, visit www.gradall.com or call 800-445-4752.

Alamo Group, Inc.: For over 40 years, Alamo Group has been a world leader in the design, manufacture, distribution, and service of high-quality equipment for right-of-way maintenance and agriculture. Alamo products include tractor and truck mounted mowing and other vegetation maintenance equipment, excavators, street sweepers, vacuum trucks, snow removal equipment, pothole patchers, agricultural attachments, and related aftermarket parts and services. Alamo currently produces and assembles products in 16 principal facilities worldwide, sold through Alamo Group's marketing organizations and Alamo’s extensive independent worldwide dealer networks under various trademarks and trade names. These include Alamo Industrial, Tiger, Schwarze, Gradall, Vacall, Nite-Hawk, Henke Manufacturing, Schulte, Rhino, M & W, SMC, Herschel, Valu-Bilt, Bomford, Spearhead, McConnel, Twose, SMA, Forges Gorce, Faucheux, Rousseau, Rivard, and others. Alamo Group went public in 1993 and since 1995 has been listed on the New York Stock Exchange as ALG. Visit our website at www.alamo-group.com

BUILT TO WORK.

BUILT TO LAST.

Manufactured in America with the highest quality standards, Gradall Metal Mill maintenance machines are built for hard work and a long machine life. Backed by the Gradall name, a well-known and respected brand worldwide in the construction industry.